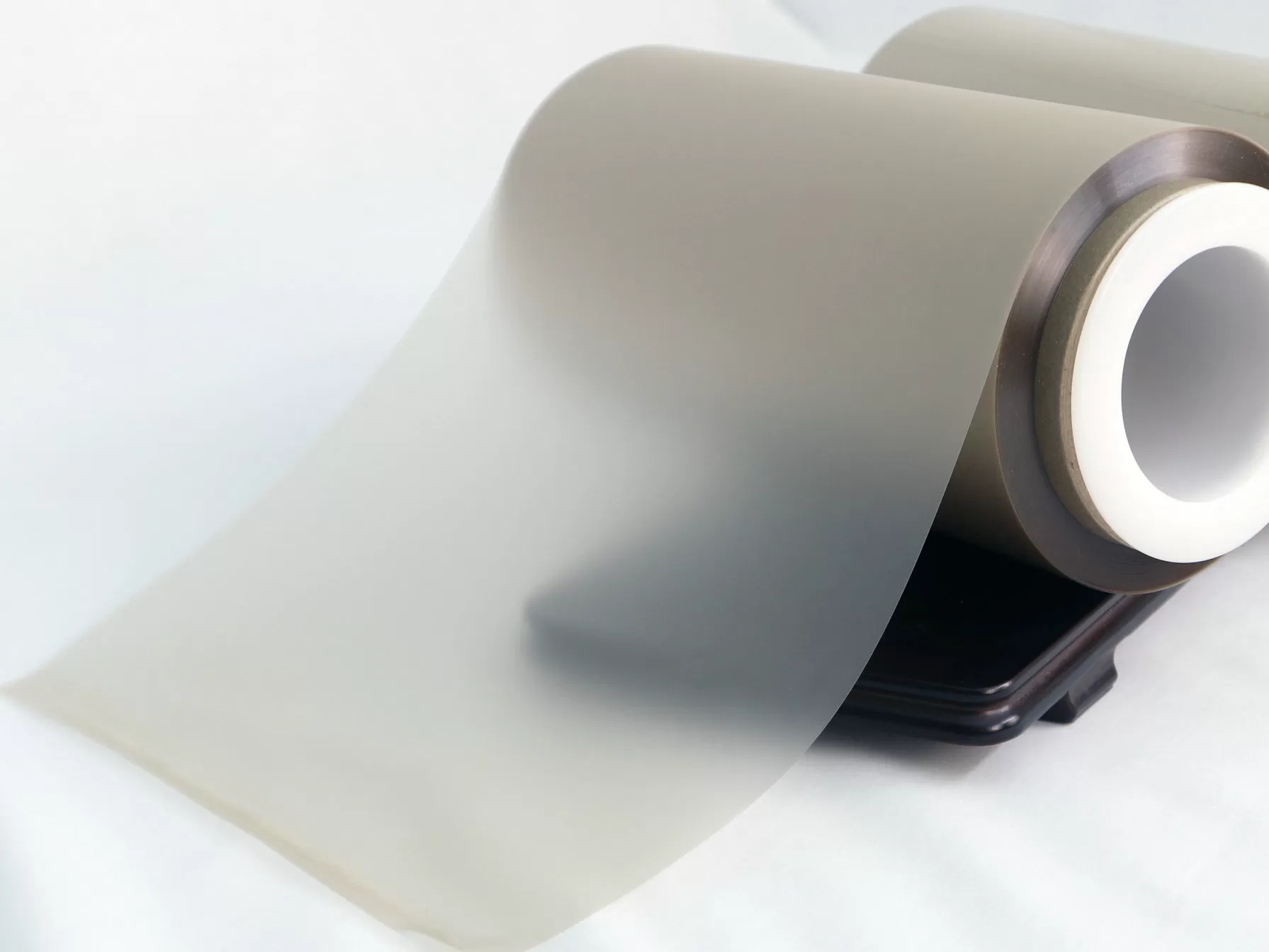

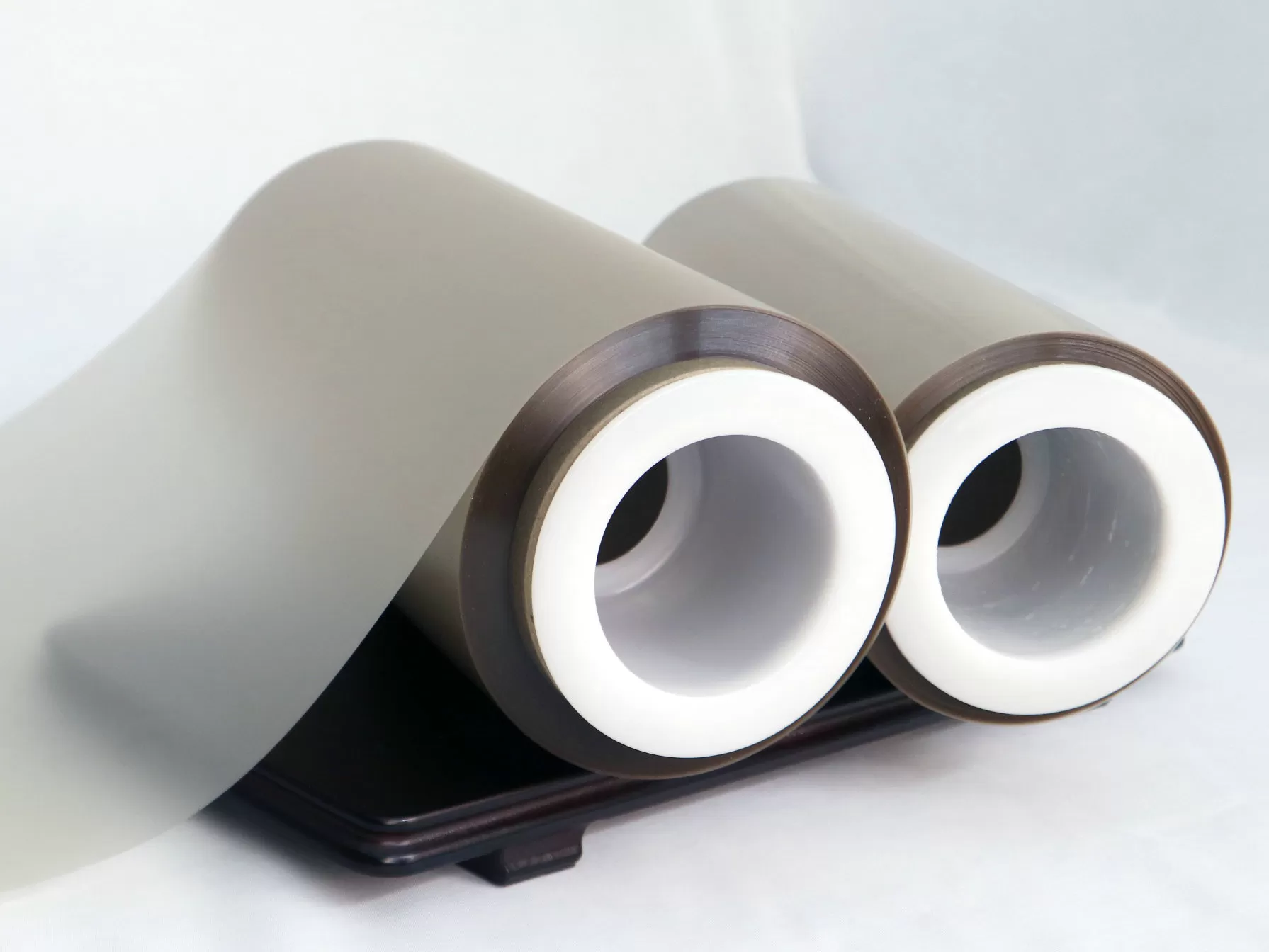

OVERVIEW of PEEK Film Material

Amorphous PEEK Film is a remarkable material prized for its unique blend of qualities. With exceptional optical clarity, chemical resistance, and remarkable durability, it stands as the preferred choice across a multitude of industries. Whether you're crafting precision optical components, developing cutting-edge medical devices, or seeking durable solutions for various applications, Amorphous PEEK Film delivers unmatched versatility and performance. Explore the potential of this exceptional material and see how it can elevate your product's performance, inspire innovation, and meet the demands of even the most challenging projects.

FEATURES, BENEFITS and APPLICATIONS of PEEK Thermoplastic Film

Material: Amorphous, Semi-crystalline and Mineral Filled Semi-crystalline.

PEEK (polyetheretherketone) Film Provides:

● High Temperature Performance

● Excellent Tribological Properties

● Broad Chemical Resistance

● High-Strength & Toughness

● Electrical Stability & Radiation Resistance

● Low Smoke & Toxic Gas Emission

● High-Purity, extremely low extractables

Applications:

● Micro speaker diaphragm, dome tweeter.

● Presslire exchanger and senior oliaphragin.

● Aerospace high-speed rail insulation and TAB heat insulation components.

● Thrust washers for micro motors, gaskets for automobiles.

● High-temperature resistant label, pressure sensitive tape substrate.

● Insulation layer of electric vehicle battery.

● Flexible film surface heater.

● Wire, cable, insulation and wrcop sheaths.

Size

Thicknesses between 10µm (0,01 mm) up to 1000µm (1 mm);

Width usually about 420, 650, 1100mm, but customer preferences of special sizes or thicknesses will be provided.