Carbon Fiber Filled PEEK

Carbon Fiber PEEK - It's a composite material that combines carbon fibers with PEEK (Polyether Ether Ketone) resin. This combination results in a material that inherits the excellent mechanical properties of both carbon fiber and PEEK, making it strong, lightweight, and resistant to chemicals and high temperatures. Carbon Fiber PEEK is commonly used in industries such as aerospace, automotive, medical, and manufacturing for applications that require high-performance materials with exceptional strength-to-weight ratios and thermal stability.

Carbon Fiber PEEK Material Properties

_______________________________________________________________________________________________________________________________________________________________________

Introduction to Carbon Fiber PEEK

Carbon Fiber PEEK is a composite material that integrates the benefits of polyetheretherketone (PEEK) with the enhanced mechanical properties of carbon fibers. This combination results in a material that is not only strong and lightweight but also resistant to heat, chemicals, and wear, making it a preferred choice for industries such as aerospace, automotive, and medical.

Key Properties of Carbon Fiber PEEK

Mechanical Properties: Carbon Fiber PEEK exhibits higher mechanical strength and stiffness compared to unreinforced PEEK, with an ultimate tensile strength reaching up to 138 MPa and a tensile modulus of up to 14 GPa. This makes it suitable for high-load applications.

Thermal Properties: The addition of carbon fibers increases thermal conductivity, reducing thermal expansion and providing greater dimensional stability at high temperatures.

Chemical Resistance: It retains PEEK's excellent chemical resistance, making it suitable for use in corrosive environments.

Applications of Carbon Fiber PEEK

Aerospace: Used in aircraft components due to its high strength-to-weight ratio and resistance to extreme temperatures.

Automotive: Utilized for parts requiring high mechanical performance and thermal stability.

Medical: Employed in medical devices and instruments due to its biocompatibility and resistance to sterilization processes.

Cost Considerations

The cost of Carbon Fiber PEEK varies based on the carbon fiber content and application. Generally, it is expensive than unreinforced PEEK, but its enhanced properties justify the cost in demanding applications. Our prices can range from $40 to over $70 per kilogram, depending on the specific formulation.

Carbon Fiber PEEK Material Properties

Density: Approximately 1.33 g/cm³, which is slightly higher than unreinforced PEEK.

Operating Temperature: Can maintain mechanical properties up to 300°C (572°F).

Chemical Resistance: Resistant to most organic solvents, acids, and bases.

By leveraging Carbon Fiber PEEK's superior material properties, industries can develop innovative solutions that meet the demands of high-performance applications, providing a cost-effective alternative to metals in many cases.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

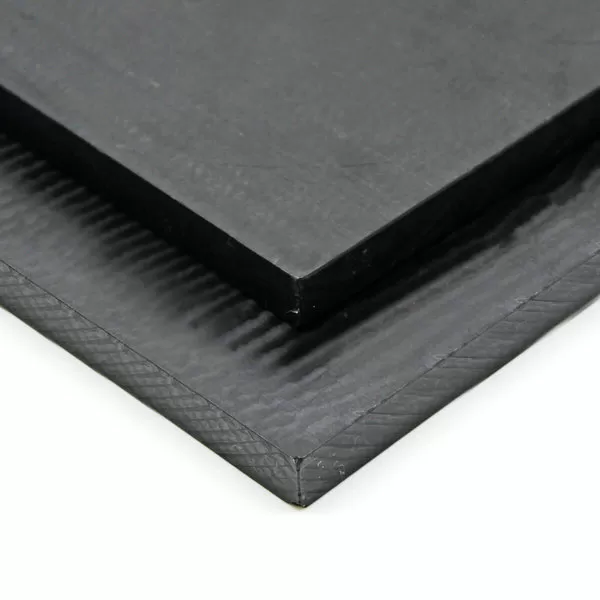

Carbon Fiber PEEK Composite Sheet Size

| NO. | Dimension (mm) | Weight ( g ) |

| 1 | 0.5*700*1000 | 480 |

| 2 | 1*700*1000 | 950 |

| 3 | 2*700*1000 | 1900 |

| 4 | 3*700*1000 | 2800 |

| 5 | 4*650*1000 | 3400 |

| 6 | 5*650*1000 | 4300 |

| 7 | 67×31×1000 | 2700 |

| 8 | 80x15x1000 | 1560 |

| 9 | 100x25x1000 | 3100 |

| 10 | 120x38x1000 | 5500 |

| 11 | 195×33×1000 | 8365 |

| 12 | 175x162×1000 | 36855 |

| 13 | 395x12.5x1000 | 6419 |

| 14 | 422x15x1000 | 8229 |

| 15 | 422x66x1000 | 36207 |

| 16 | Insulation block (with Utype)280x45x1000 | 15000 |

| 17 | 600×6x1000 | 4680 |

| 18 | 600x8×1000 | 6240 |

| 19 | 600×9×1000 | 7020 |

| 20 | 600x15x1000 | 11700 |

| 21 | 600×20x1000 | 15600 |

| 22 | 600×25×1000 | 19500 |

| 23 | 600x30x1000 | 23400 |

| 24 | 600x35×1000 | 27300 |

| 25 | 600×40×1000 | 31200 |

| 26 | 600x45x1000 | 35100 |

| 27 | 600x50×1000 | 39000 |

| 28 | 600x60x1000 | 46800 |

| 29 | 800x20x1000 | 20800 |

| 30 | 800x30x1000 | 31200 |