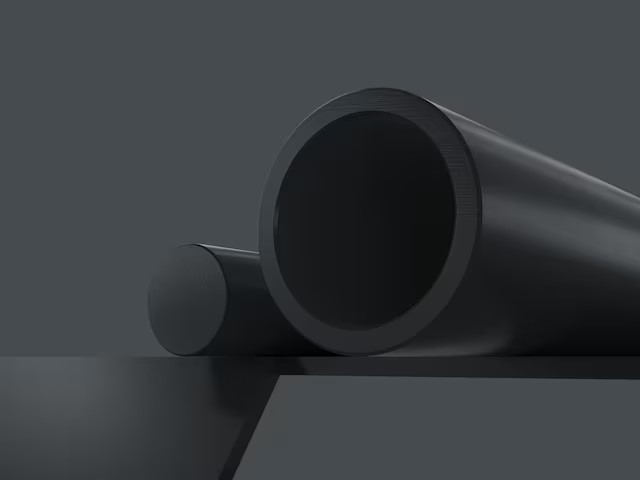

PEEK Carbon Fiber Reinforced Material

Carbon Fiber Reinforced PEEK (CFR-PEEK) combines PEEK’s exceptional thermal/chemical resistance with carbon fiber’s strength. With mechanical properties like 138 MPa tensile strength and temperature resistance up to 300°C, it’s ideal for high-stress applications. Available as PEEK 30 carbon filled or custom formulations.

_______________________________________________________________________________________________________________________________________________________________________

Carbon Fiber Reinforced PEEK – Advanced Composite for High-Performance Applications

Carbon Fiber Reinforced PEEK is a premium high-performance thermoplastic composite, engineered to deliver superior mechanical properties for extreme environments. This advanced material combines the exceptional thermal and chemical resistance of PEEK with the high strength and stiffness of carbon fiber reinforcement.

Our carbon filled PEEK offers remarkable wear resistance, lightweight properties, and high tensile strength, making it the preferred choice for demanding applications in aerospace, automotive, and industrial sectors. With multiple formulations, including peek 30 carbon reinforced and peek 30 carbon filled, we provide tailored solutions to meet specific performance requirements.

Unmatched Mechanical Properties

Carbon Fiber Reinforced PEEK delivers enhanced mechanical performance over standard PEEK, with:

Tensile Strength: Up to 138 MPa (35% stronger than unreinforced PEEK).

Stiffness: Tensile modulus of 14 GPa (76% stiffer).

Thermal Stability: Operates continuously at 250–300°C.

Wear Resistance: 87 Shore D hardness for reduced friction and longevity.

Available in PEEK 30 carbon filled (30% carbon fiber) and other formulations, this material is engineered for applications demanding lightweight, durable solutions.

Cost-Effective Performance

While Carbon Fiber Reinforced PEEK cost is higher than standard PEEK, its durability and reduced lifecycle expenses justify the investment:

Longevity: Outlasts metals and plastics in harsh environments.

Weight Savings: 40–60% lighter than aluminum, lowering fuel/energy costs.

Low Maintenance: Resists corrosion, chemicals, and fatigue.

For precision components like bearings or medical implants, carbon loaded PEEK reduces long-term operational costs through reliability and minimal downtime.

Applications & Solutions

Carbon Reinforced PEEK solves challenges across industries:

Aerospace: Engine components, brackets, and housings requiring high strength-to-weight ratios.

Medical: 3D-printed implants (e.g., bone plates) with PEEK 30 carbon reinforced biocompatibility.

Automotive: Lightweight under-hood parts withstanding extreme temperatures.

Industrial: Seals, bushings, and pump parts for corrosive/abrasive environments.

Why Choose Carbon Filled PEEK?

Superior to Metals: Combines metal-like strength with polymer flexibility and corrosion resistance.

Customizable: Available as carbon reinforced PEEK (10–30% fiber content) for tailored performance.

Dimensional Stability: Low thermal expansion ensures precision in fluctuating temperatures.

Technical Specifications

| Property | Carbon Reinforced PEEK | Unreinforced PEEK |

| Tensile Strength | 138 MPa | 89 MPa |

| Thermal Conductivity | 0.9–1.1 W/mK | 0.25 W/mK |

| Continuous Use Temp | 300°C | 260°C |

| Cost (Per kg) | $40–$70 | $35–$65 |

Conclusion

Carbon Fiber Reinforced PEEK (CFR-PEEK) is the ultimate solution for high-performance applications requiring strength, heat resistance, and lightweight design. Whether you need PEEK 30 carbon filled for medical devices or carbon loaded PEEK for aerospace, this material delivers unmatched mechanical properties and long-term cost savings.

This content integrates keywords naturally while providing actionable technical insights, helping visitors understand how CFR-PEEK solves industry-specific challenges.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

Carbon Fiber Reinforced PEEK Sheet Size

| NO. | Dimension (mm) | Weight ( g ) |

| 1 | 0.5*700*1000 | 480 |

| 2 | 1*700*1000 | 950 |

| 3 | 2*700*1000 | 1900 |

| 4 | 3*700*1000 | 2800 |

| 5 | 4*650*1000 | 3400 |

| 6 | 5*650*1000 | 4300 |

| 7 | 67×31×1000 | 2700 |

| 8 | 80x15x1000 | 1560 |

| 9 | 100x25x1000 | 3100 |

| 10 | 120x38x1000 | 5500 |

| 11 | 195×33×1000 | 8365 |

| 12 | 175x162×1000 | 36855 |

| 13 | 395x12.5x1000 | 6419 |

| 14 | 422x15x1000 | 8229 |

| 15 | 422x66x1000 | 36207 |

| 16 | Insulation block (with Utype)280x45x1000 | 15000 |

| 17 | 600×6x1000 | 4680 |

| 18 | 600x8×1000 | 6240 |

| 19 | 600×9×1000 | 7020 |

| 20 | 600x15x1000 | 11700 |

| 21 | 600×20x1000 | 15600 |

| 22 | 600×25×1000 | 19500 |

| 23 | 600x30x1000 | 23400 |

| 24 | 600x35×1000 | 27300 |

| 25 | 600×40×1000 | 31200 |

| 26 | 600x45x1000 | 35100 |

| 27 | 600x50×1000 | 39000 |

| 28 | 600x60x1000 | 46800 |

| 29 | 800x20x1000 | 20800 |

| 30 | 800x30x1000 | 31200 |