PEEK Material Composition

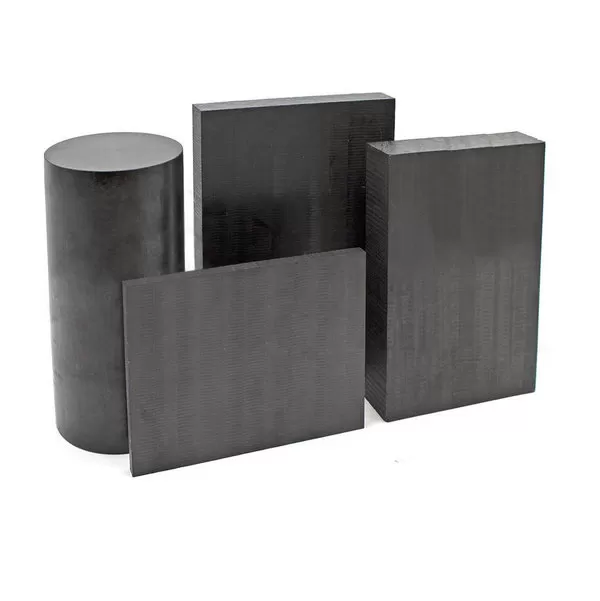

Our Composite PEEK materials, featuring ARKPEEK-CF30, ARKPEEK-GF30, and ARKPEEK-MOD, offer tailored solutions for demanding applications. These materials combine Polyether Ether Ketone (PEEK) with carbon or glass fibers, enhancing mechanical strength, stiffness, and chemical resistance.

PEEK Composite Material Properties

_______________________________________________________________________________________________________________________________________________________________________

Introduction to Composite PEEK Materials

Composite PEEK materials are engineered by integrating Polyether Ether Ketone (PEEK) with reinforcing fibers such as carbon or glass. This synergy enhances the inherent properties of PEEK, making it suitable for applications requiring high mechanical strength, thermal stability, and chemical resistance. Our product lineup includes ARKPEEK-1000, ARKPEEK-CF30, ARKPEEK-GF30, and ARKPEEK-MOD, each designed to address specific engineering challenges.

Material Composition and Properties

ARKPEEK-1000: This is 100% pure PEEK, renowned for its exceptional toughness, impact resistance, and chemical stability. It is ideal for applications where reliability and resilience are crucial.

ARKPEEK-CF30: This material combines 30% carbon fibers with 70% PEEK, offering enhanced mechanical strength, stiffness, and thermal conductivity. It is suitable for applications requiring high performance and weight reduction.

ARKPEEK-GF30: Reinforced with 30% glass fibers, this material provides improved mechanical strength and stiffness compared to unfilled PEEK. It is ideal for applications where high static loads and dimensional stability are necessary.

ARKPEEK-MOD: This modified PEEK includes 10% carbon fibers, 10% PTFE, and 10% graphite, offering excellent wear resistance, low friction, and high mechanical strength. It is designed for demanding environments where standard PEEK materials may not suffice.

Material Properties

Mechanical Properties: Our Composite PEEK materials exhibit high tensile strength, stiffness, and resistance to wear and fatigue. The addition of carbon or glass fibers further enhances these properties, making them suitable for demanding applications.

Thermal Properties: PEEK composites have a high glass transition temperature and continuous use temperature, ensuring stability in extreme thermal environments.

Chemical Resistance: The chemical composition of PEEK provides excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents.

Uses of Composite PEEK Materials

These materials are versatile and find applications in various industries:

Aerospace: Used for structural components and machinery parts where high strength-to-weight ratios are essential.

Automotive: Ideal for components requiring high mechanical strength, wear resistance, and thermal stability.

Medical: Suitable for medical devices and implants due to their biocompatibility and high performance.

Our Composite PEEK materials, including ARKPEEK-1000, ARKPEEK-CF30, ARKPEEK-GF30, and ARKPEEK-MOD, are designed to address complex engineering challenges by offering tailored solutions with enhanced mechanical, thermal, and chemical properties. Whether you need carbon or glass fiber reinforcement, our products are engineered to meet the most stringent requirements across various industries.