PEEK CA30 Material Performance

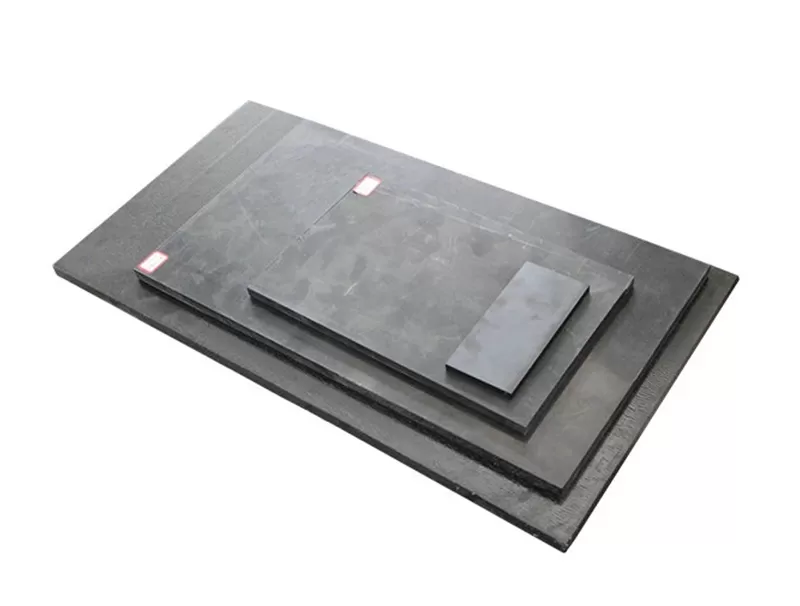

Our Carbon Fiber Reinforced PEEK Sheets, such as the 30% carbon fiber reinforced PEEK CA30 sheet, offer enhanced mechanical strength, stiffness, and thermal conductivity. Ideal for aerospace, automotive, and medical applications, these sheets ensure reliability under extreme conditions.

_______________________________________________________________________________________________________________________________________________________________________

Introduction to Carbon Fiber Reinforced PEEK Sheets

Carbon Fiber Reinforced PEEK Sheets are high-performance composite materials engineered by integrating Polyether Ether Ketone (PEEK) with carbon fibers. This unique combination enhances the inherent properties of PEEK, making it suitable for applications requiring high mechanical strength, thermal stability, and chemical resistance.

Material Properties

Mechanical Properties: Our Carbon Fiber Reinforced PEEK Sheets, such as the PEEK CA30 material, exhibit high tensile strength, stiffness, and resistance to wear and fatigue. The addition of 30% carbon fibers significantly enhances these properties, making them suitable for demanding applications.

Thermal Properties: These sheets have a high glass transition temperature and continuous use temperature, ensuring stability in extreme thermal environments. The carbon fibers also enhance thermal conductivity, reducing thermal expansion and improving part life in sliding applications.

Chemical Resistance: The chemical composition of PEEK provides excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents.

Applications of Carbon Fiber Reinforced PEEK Sheets

These sheets are versatile and find applications in various industries:

Aerospace: Used for structural components, insulation materials, and radiation shields in spacecraft and satellites due to their ability to withstand extreme temperatures, radiation, and vacuum conditions.

Automotive: Ideal for components requiring high mechanical strength, wear resistance, and thermal stability. They are used in structural components, under-the-hood parts, and interior components to enhance fuel efficiency and safety.

Medical: Suitable for medical devices and implants due to their biocompatibility and high performance. They are used in applications such as surgical instruments and implantable devices.

Energy and Oil & Gas: Valued for their chemical resistance and high-temperature stability, making them suitable for applications in harsh environments.

Electronics: Used as electrical insulation materials due to their ability to maintain insulation properties under high temperatures and humidity.

30% Carbon Fiber PEEK Sheet (PEEK CA30)

Our 30% Carbon Fiber PEEK Sheet, also known as PEEK CA30, is a popular choice for applications requiring a balance between mechanical properties and cost. It offers:

Enhanced Mechanical Strength: With a tensile strength of approximately 200 MPa and a flexural modulus of about 19 GPa.

Improved Thermal Conductivity: Reducing thermal expansion and enhancing part life in sliding applications.

High Chemical Resistance: Retaining mechanical properties even in harsh environments.

Conclusion

Our Carbon Fiber Reinforced PEEK Sheets, including the 30% carbon fiber reinforced PEEK CA30 sheet, are designed to address complex engineering challenges by offering tailored solutions with enhanced mechanical, thermal, and chemical properties. Whether you need high-performance materials for aerospace, automotive, medical, energy, or electronics applications, our products are engineered to meet the most stringent requirements across various industries.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK Materials

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

Carbon Reinforced PEEK Sheet Size

| NO. | Dimension (mm) | Weight ( g ) |

| 1 | 0.5*700*1000 | 480 |

| 2 | 1*700*1000 | 950 |

| 3 | 2*700*1000 | 1900 |

| 4 | 3*700*1000 | 2800 |

| 5 | 4*650*1000 | 3400 |

| 6 | 5*650*1000 | 4300 |

| 7 | 67×31×1000 | 2700 |

| 8 | 80x15x1000 | 1560 |

| 9 | 100x25x1000 | 3100 |

| 10 | 120x38x1000 | 5500 |

| 11 | 195×33×1000 | 8365 |

| 12 | 175x162×1000 | 36855 |

| 13 | 395x12.5x1000 | 6419 |

| 14 | 422x15x1000 | 8229 |

| 15 | 422x66x1000 | 36207 |

| 16 | Insulation block (with Utype)280x45x1000 | 15000 |

| 17 | 600×6x1000 | 4680 |

| 18 | 600x8×1000 | 6240 |

| 19 | 600×9×1000 | 7020 |

| 20 | 600x15x1000 | 11700 |

| 21 | 600×20x1000 | 15600 |

| 22 | 600×25×1000 | 19500 |

| 23 | 600x30x1000 | 23400 |

| 24 | 600x35×1000 | 27300 |

| 25 | 600×40×1000 | 31200 |

| 26 | 600x45x1000 | 35100 |

| 27 | 600x50×1000 | 39000 |

| 28 | 600x60x1000 | 46800 |

| 29 | 800x20x1000 | 20800 |

| 30 | 800x30x1000 | 31200 |