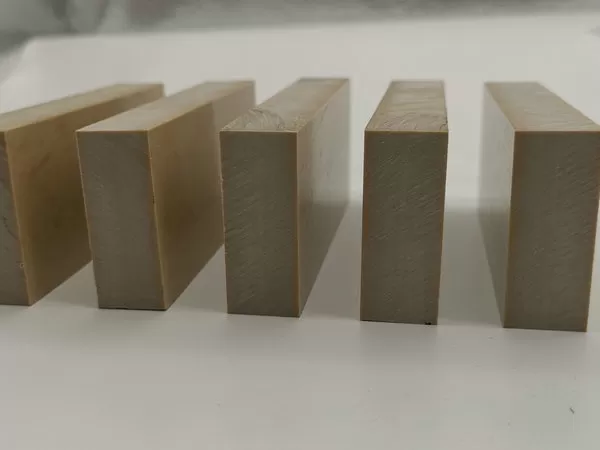

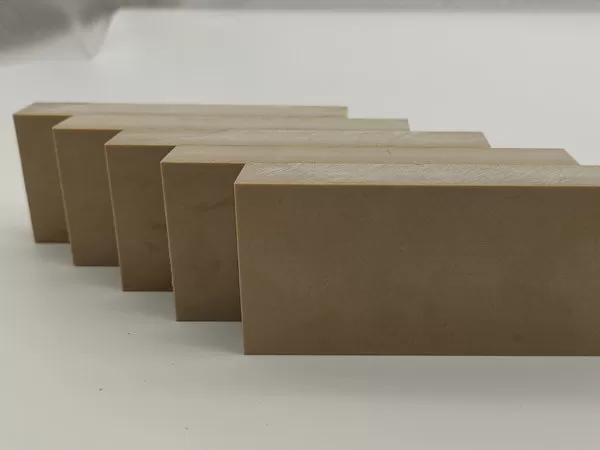

PEEK Block For Machining

We supply high-performance PEEK plastic blocks cut to your exact machining requirements. From custom PEEK block cutting to complex shapes, our ISO-certified processes ensure superior PEEK machinability, tight tolerances, and stress-free finishes. Perfect for prototypes or production runs.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Plate Blocks for Precision Machined Parts

As a leading PEEK manufacturer, we provide PEEK plastic blocks and custom-cut shapes optimized for machining high-performance components. Our services ensure your raw PEEK material is pre-cut to exact dimensions, minimizing waste and streamlining your production process.

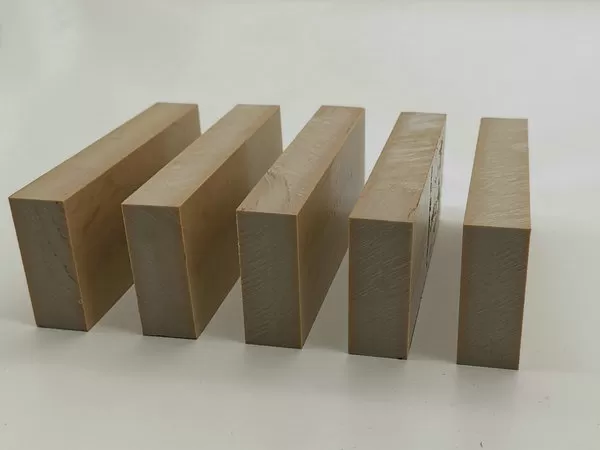

Solve Machining Challenges with Custom-Cut PEEK Blocks

Precision PEEK Block Cutting: Achieve ±0.1mm tolerances for blocks tailored to your CNC or manual machining workflows.

Complex Shapes & Sizes: Need intricate PEEK cutting shapes for gears, bushings, or medical implants? Our advanced cutting tools handle even the most demanding geometries.

Material Expertise: Leverage our knowledge of PEEK machinability to avoid common issues like cracking, melting, or tool wear.

Grades for Every Application: Standard, glass-filled, or carbon-filled PEEK blocks for machining—all optimized for thermal stability (up to 260°C/480°F) and chemical resistance.

Technical Advantages of Our PEEK Blocks

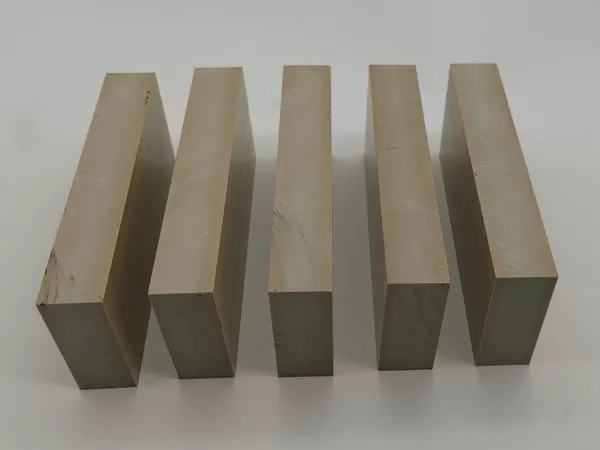

Optimized for Machining

Low moisture absorption and high dimensional stability ensure consistent results during milling, turning, or drilling.

Custom annealing options to reduce internal stresses in PEEK material machining.

Industry-Specific Solutions

Medical: FDA-compliant blocks for surgical tools, implants, and MRI-compatible components.

Aerospace: High-strength PEEK blocks for lightweight bearings, seals, and engine components.

Automotive: Machinable blocks for fuel system parts, sensor housings, and thermal insulators.

Electronics: Conductive (carbon-filled) or insulating blocks for EMI shielding and PCB fixtures.

Why Choose Our PEEK Cutting Services?

✔ Advanced Cutting Technology: Laser, CNC, or waterjet cutting for burr-free edges and smooth surfaces.

✔ Custom Sizes & Shapes: From standard blocks to bespoke PEEK cutting custom designs—no order too complex.

✔ Fast Turnaround: Cut-to-order PEEK blocks shipped globally from our ISO-certified facility in China.

✔ Quality Guaranteed: Rigorous inspection of PEEK material for machining, including CMM checks and surface quality reports.

Unlock the Full Potential of PEEK Machining

Whether you need a single prototype block or bulk orders, our PEEK block cutting services ensure your material is precision-ready. Give your CAD file or share your specs—we deliver machining-grade PEEK blocks tailored to your needs.

_______________________________________________________________________________________________________________________________________________________________________

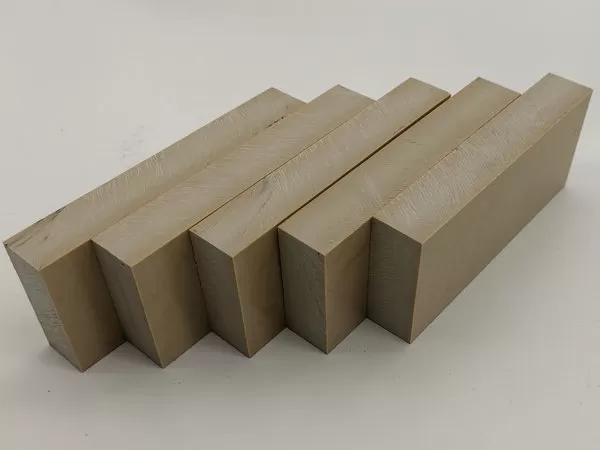

PEEK Block Materials

ARKPEEK-1000: 100% Natural PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.