PEEK Material Performance

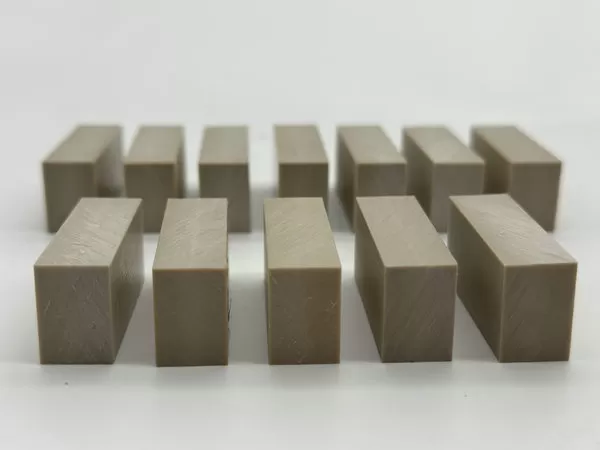

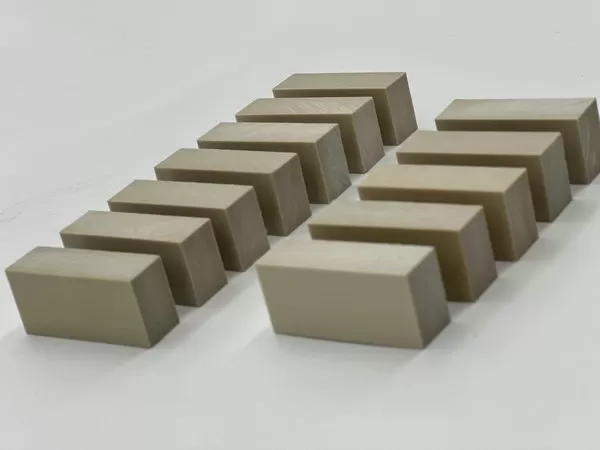

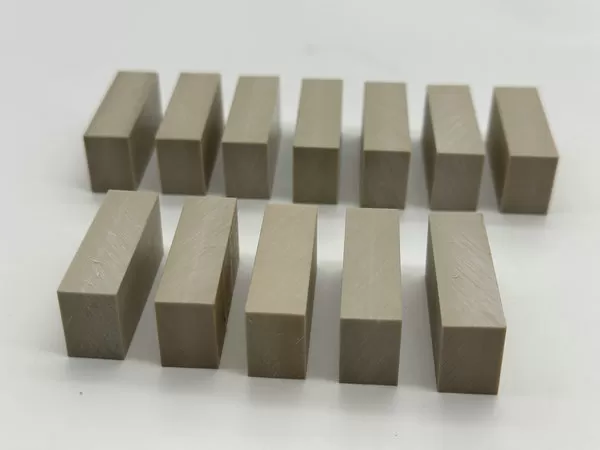

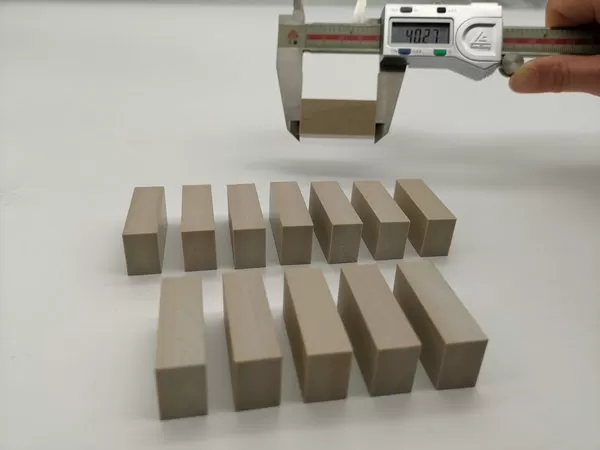

Unfilled 100% Pure PEEK, also know as our material grade ARKPEEK-1000, is a remarkable high-performance thermoplastic, boasts outstanding chemical resistance and thermal stability. Its versatile applications span industries where reliability and resilience are crucial. Explore the diverse uses of unfilled PEEK and harness its exceptional properties for your specific project requirements.

_______________________________________________________________________________________________________________________________________________________________________

PEEK (Polyetheretherketone) is renowned for its superior performance across a wide range of temperatures and extreme conditions. It is a semicrystalline thermoplastic that retains its mechanical and chemical resistance properties even at high temperatures, making it a favorite in industries like aerospace, automotive, and medical.

Key Features and Benefits

High Thermal Stability: PEEK sheets can withstand continuous working temperatures up to 250°C, ensuring durability in high-heat environments.

Chemical Resistance: Excellent resistance to chemicals, making it suitable for applications where exposure to harsh substances is common.

Mechanical Strength: Offers high tensile strength and stiffness, providing structural integrity under stress.

Biocompatibility: FDA-approved for use in medical applications, ensuring safety for implantable devices.

Stock Options and Pricing

We offer a comprehensive range of PEEK sheet stock sizes, including 12″ x 12″, 12″ x 24″, and 24″ x 48″, with various thickness options to meet your specific needs. Our PEEK sheet stock prices are competitive, ensuring you get the best value for your budget. Whether you're looking for PEEK sheet stock for sale or need to know the price of PEEK per kg, we provide transparent pricing to help you plan your projects effectively.

How do you cut PEEK plastic?

There are multiple ways to cut PEEK, including band sawing, laser cutting, and using cutting tools:

Band sawing

This is the preferred method for cutting PEEK shapes, including straight and contoured cuts of plate, rod, and tubular bar. When choosing a saw blade, consider the material's thickness and desired precision, and make sure it has enough clearance to reduce heat buildup. Triple chip blades with 2.5–3.5 teeth per inch are recommended, along with a band saw speed of 2500 ft per minute and coolant.

Laser cutting

Ultraviolet (UV) lasers are ideal for cutting PEEK materials and producing precise parts.

Cutting tools

Silicon carbide cutting tools are usually sufficient for machining PEEK, but diamond tools are needed if the PEEK is reinforced with carbon fiber or tight tolerances are required. PEEK is abrasive and can damage cutting tools, so carbide tooling is recommended for short runs, while polycrystalline (PCD) tooling may be better for long runs of PEEK reinforced with glass or carbon fiber. Because PEEK doesn't dissipate heat like metals do, it's important to cool it during machining to prevent breakage or deformation. Standard liquid coolant can be used, but pressurized air is better for medical-grade PEEK to avoid compromising its biocompatibility.

Solving Your Challenges

Whether you're designing components for aerospace, automotive, or medical devices, our PEEK sheets are designed to help you overcome the challenges of high-performance applications. With their excellent thermal and mechanical properties, you can create solutions that are both durable and reliable.

Why Choose Our PEEK Sheets?

Quality Assurance: Our sheets are manufactured to ensure consistency and reliability.

Customer Support: Our team is dedicated to helping you find the right PEEK sheet for your project.

Competitive Pricing: We offer competitive pricing without compromising on quality.

By choosing our PEEK sheet stock, you're not just buying a material; you're investing in a solution that will help you achieve your project goals with confidence.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Plastic Material Grades

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range of PEEK Rod is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Sheet Stock Sizes

| NO. | Dimension (mm) | Weight ( g ) |

| 1 | 0.5*700*1000 | 480 |

| 2 | 1*700*1000 | 950 |

| 3 | 2*700*1000 | 1900 |

| 4 | 3*700*1000 | 2800 |

| 5 | 4*650*1000 | 3400 |

| 6 | 5*650*1000 | 4300 |

| 7 | 67×31×1000 | 2700 |

| 8 | 80x15x1000 | 1560 |

| 9 | 100x25x1000 | 3100 |

| 10 | 120x38x1000 | 5500 |

| 11 | 195×33×1000 | 8365 |

| 12 | 175x162×1000 | 36855 |

| 13 | 395x12.5x1000 | 6419 |

| 14 | 422x15x1000 | 8229 |

| 15 | 422x66x1000 | 36207 |

| 16 | Insulation block (with Utype)280x45x1000 | 15000 |

| 17 | 600×6x1000 | 4680 |

| 18 | 600x8×1000 | 6240 |

| 19 | 600×9×1000 | 7020 |

| 20 | 600x15x1000 | 11700 |

| 21 | 600×20x1000 | 15600 |

| 22 | 600×25×1000 | 19500 |

| 23 | 600x30x1000 | 23400 |

| 24 | 600x35×1000 | 27300 |

| 25 | 600×40×1000 | 31200 |

| 26 | 600x45x1000 | 35100 |

| 27 | 600x50×1000 | 39000 |

| 28 | 600x60x1000 | 46800 |

| 29 | 800x20x1000 | 20800 |

| 30 | 800x30x1000 | 31200 |