PEEK Thermoplastic Material

Our PEEK Thermoplastic is engineered for exceptional performance in harsh environments. With a unique thermoplastic peek formula and high-quality peek thermoplastic composite characteristics, it delivers outstanding peek plastic thermal properties and operates across a wide peek plastic temperature range. Perfect for industrial, aerospace, automotive, and electronics applications—order now for a reliable solution.

_______________________________________________________________________________________________________________________________________________________________________

Introduction to PEEK Thermoplastic

Polyetheretherketone (PEEK) thermoplastic is a high-performance engineering material celebrated for its outstanding mechanical properties, thermal stability, and chemical resistance. Its versatility makes it a preferred choice for various industries, including aerospace, automotive, medical, and electronics.

Key Properties of PEEK Thermoplastic

Thermal Properties: PEEK exhibits a high glass transition temperature of 143°C and a melting point of 343°C, allowing it to withstand continuous use at temperatures up to 260°C and short-term exposure to 310°C.

Chemical Resistance: It offers excellent resistance to harsh chemicals, including steam, water, and sea water, making it suitable for applications in aggressive environments.

Mechanical Strength: PEEK maintains its stiffness and strength under high pressure and extreme temperatures, ensuring reliability in critical components.

Applications of PEEK Thermoplastic

Aerospace: Used in critical engine parts and aircraft exterior components due to its high temperature resistance and tribological properties.

Automotive: Replaces metals in under-the-hood components, offering weight reduction and noise dampening.

Medical: Utilized in implants and medical devices due to its biocompatibility and ability to withstand autoclaving.

Electronics: Serves as an electrical insulator in connectors and cable insulation, ensuring reliability across fluctuating temperatures.

PEEK thermoplastic stands as a pinnacle of versatility and reliability in industrial applications. With superior mechanical properties, chemical resistance, and thermal stability, PEEK serves as an essential material across aerospace, automotive, and medical sectors. From structural components to precision parts, PEEK thermoplastic delivers consistent performance under diverse conditions, meeting stringent engineering standards with its durability and precision.

Formula and Composition

The chemical formula for PEEK is generally represented as (C19H12O3)n or sometimes as (C19H14O3), depending on the source. This formula indicates that PEEK is a polymer composed of repeating units of carbon, hydrogen, and oxygen atoms.

Thermal Properties and Temperature Range

PEEK plastic exhibits low thermal conductivity, making it suitable for applications requiring thermal separation, such as in 3D printing. It can operate continuously within a temperature range of up to 260°C and withstand short-term exposure to higher temperatures.

By leveraging PEEK thermoplastic properties and composites, industries can develop innovative solutions that meet the demands of high-performance applications. Whether you're seeking to enhance mechanical strength, thermal stability, or chemical resistance, PEEK thermoplastic is an ideal material for your needs.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Thermoplastic Composites

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

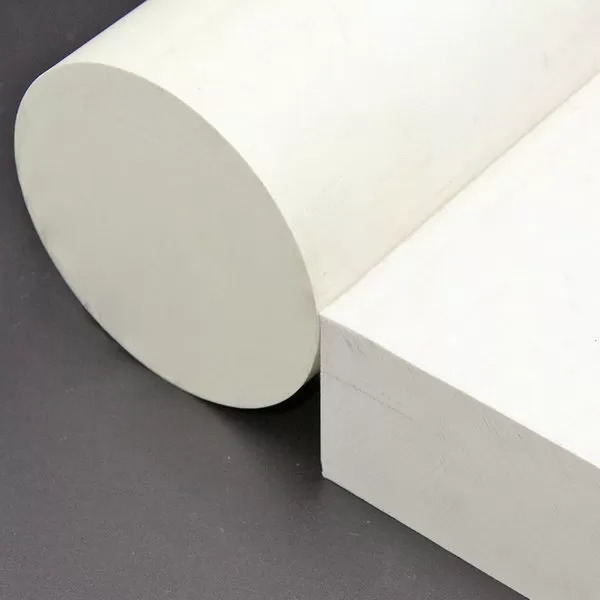

Available Shape

Pellet, Rod, Sheet, Pipe, Film and Components.