Polyether Ether Ketone PEEK Material

Polyether Ether Ketone (PEEK) is a high-performance thermoplastic with exceptional thermal stability, chemical resistance, and mechanical strength. Ideal for aerospace, medical, and industrial applications. Discover its properties, uses, safety (toxicity), and pricing to solve demanding engineering challenges.

_______________________________________________________________________________________________________________________________________________________________________

Polyether Ether Ketone (PEEK) is a premium engineering polymer renowned for its unparalleled combination of thermal stability, chemical resistance, and mechanical durability. Its semi-crystalline polyetheretherketone structure ensures performance in extreme environments, making it a go-to material for industries like aerospace, automotive, and medical devices.

Key Technical Insights

Polyetheretherketone Properties: With a density of 1.3 g/cm³, PEEK offers lightweight yet robust solutions. It withstands temperatures up to 260°C (480°F) and resists wear, creep, and hydrolysis.

Polyether Ether Ketone Uses: Perfect for implants (biocompatible), electrical insulation, and high-stress mechanical parts.

Polyetheretherketone Toxicity: Non-toxic and FDA-approved for medical use, ensuring safety in sensitive applications.

Solve Problems with PEEK

Replace metals in lightweighting projects without sacrificing strength.

Operate in corrosive or high-temperature environments where traditional plastics fail.

Access a detailed Polyether Ether Ketone datasheet for precise mechanical, thermal, and electrical specs.

Cost-Efficiency

While the Polyether Ether Ketone price is higher than standard plastics, its longevity and performance reduce long-term costs. Custom pricing is available based on volume and grade.

Whether you need material data, safety guidelines, or pricing, PEEK delivers solutions for the most demanding engineering challenges. Download our datasheet today to explore its full potential!

_______________________________________________________________________________________________________________________________________________________________________

Polyetheretherketone Grades

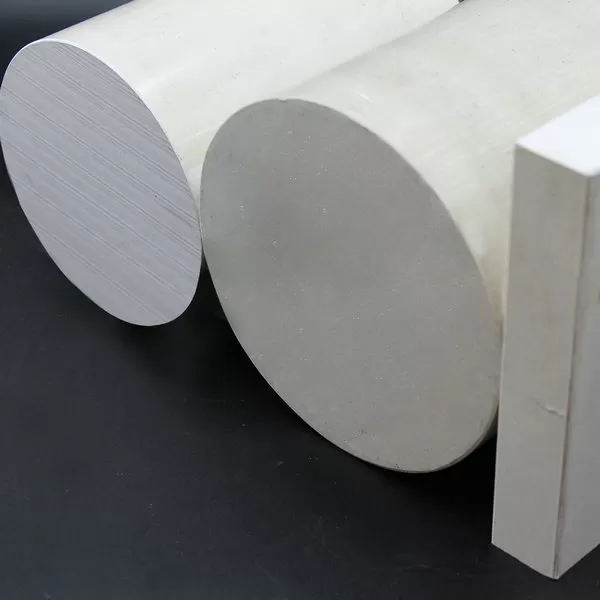

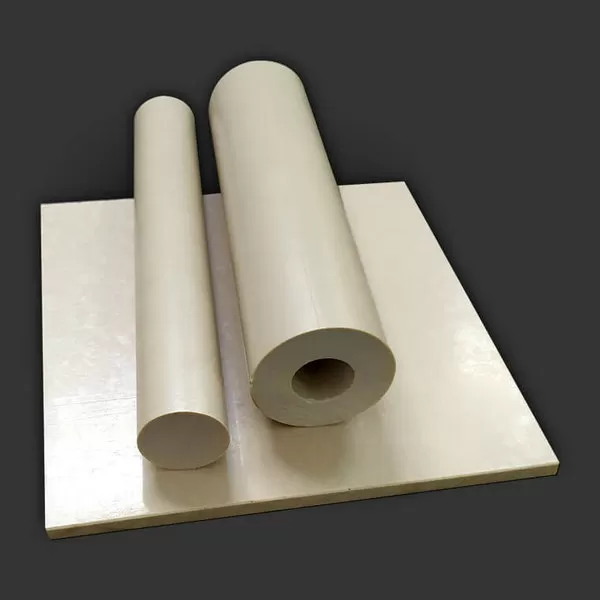

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

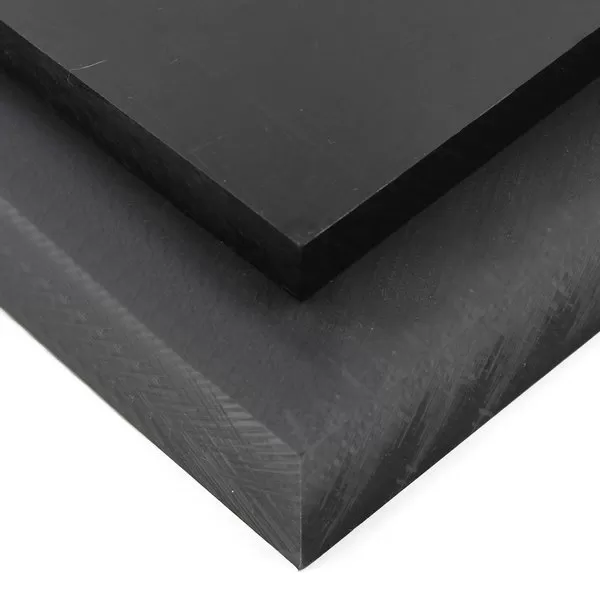

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.